3 1 Process Costing Vs. Job Order Costing Managerial Accounting

In these industries, the production process is continuous and standardized, making it difficult to determine the exact cost of producing each product unit. Process costing enables manufacturers process cost system to allocate costs across production to determine the cost per output unit. The total cost of the product that is arrived at at the end of the period is allocated according to the number of completed and unfinished products (equivalent units). This is done by dividing the total cost of the products by the number of units.

Example of Process Cost Accounting

- When a company mass produces parts but allows customization on the final product, both systems are used; this is common in auto manufacturing.

- Process costing helps in performance evaluation by providing information on the costs incurred in each stage of the production process, which allows for measuring the efficiency and effectiveness of the production process.

- Often, process costing makes sense if the individual costs or values of each unit are not significant.

- The majority of companies produce more than one product, and they use process costing by making batches of identical products, or at least highly similar products.

- Moreover, raw material needs to pass through multiple stages of production before turning into finished goods.

- In addition, the costs of inventory under each process are also identified at this change.

- In this example, two groups—administrative and manufacturing—report directly to the chief financial officer (CFO).

By effectively implementing process costing, businesses can make informed decisions, set competitive prices, and maximize profitability. It is essential for manufacturing businesses to carefully consider the factors involved in selecting a process costing method and to ensure that they implement it correctly. The food industry uses process costing to https://www.bookstime.com/articles/ecommerce-bookkeeping calculate the cost of producing food products. This industry produces food products in large quantities with a consistent manufacturing process, making process costing an ideal technique for cost calculation.

Large-Scale Production

Sometimes, after inspection, the product needs to be reworked and additional pieces are added. Because the frames have already been through each department, the additional work is typically minor and often entails simply adding an additional fastener to keep the back of the frame intact. Staff time cards can be used to track labor costs until they are assigned to production.

Real-time Cost Tracking

For the past 52 years, Harold Averkamp (CPA, MBA) has worked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online. Employees play a crucial role in the success of the process-costing system. Manufacturing companies should provide training and support to employees to ensure they understand the system and how to use it effectively.

Financial and Managerial Accounting

The total cost of producing a product is then divided by the total number of units produced to determine the cost per unit. This method benefits companies that operate in industries such as chemical manufacturing, oil refining, and food processing, where a high volume of identical products is produced. Process costing allocates costs to each production unit based on a predetermined overhead rate. This rate is determined by dividing the total overhead costs by the total number of units produced. In job costing, costs are allocated to each job or project based on the costs incurred.

Technology makes it easy to track costs as small as one fastener or ounce of glue. However, if each fastener had to be requisitioned and each ounce of glue recorded, the product would take longer to make and the direct labor cost would be higher. So, while it is possible to track the cost of each individual product, the additional information may not be worth the additional expense. Regardless of the costing system used, manufacturing costs consist of direct material, direct labor, and manufacturing overhead.

- Ore is introduced in the melting stage, alloys in the skimming stage, etc. (this is equally true for labor and overhead).

- This is done by dividing the total cost of the products by the number of units.

- By using process costing, manufacturers can identify the cost drivers and take steps to reduce costs and increase profitability.

- The carbonated drinks that the company produces pass through several production departments.

- If a process costing system does not mesh well with a company’s cost accounting systems, there are two other systems available that may be a better fit.

- Technology can automate the data collection process, reducing the risk of errors and improving the accuracy of cost calculations.

Uniform Product Costing

Assembly lines can be combined or separated based on actual production and resource management. It is much easy for management to spot the weakness of each process by comparing their cost and output. Rock City Percussion makes 8,000 hickory sticks per day, four days each week.

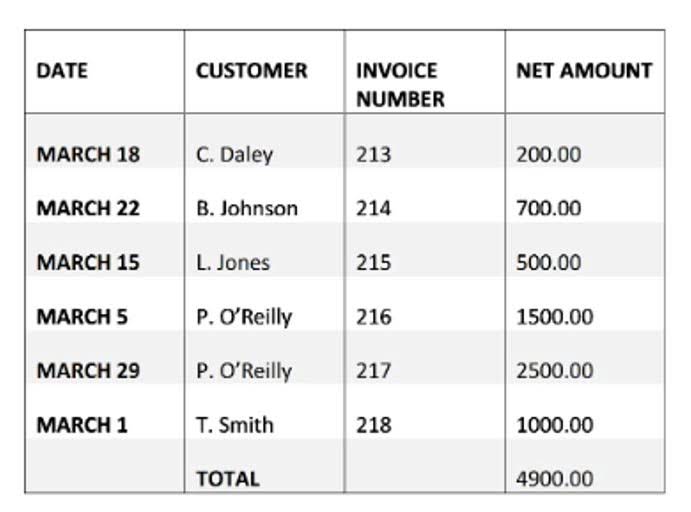

The first department in the process is the casting department, where the widgets are initially created. During the month of March, the casting department incurs $50,000 of direct material costs and $120,000 of conversion costs (comprised of direct labor and assets = liabilities + equity factory overhead). The widgets then move to the trimming department for further work, and these per-unit costs will be carried along with the widgets into that department, where additional costs will be added.

Job Order Costing vs Process Costing

Job order systems are custom orders because the cost of the direct material and direct labor are traced directly to the job being produced. For example, General Mills uses process costing for its cereal, pasta, baking products, and pet foods. Process costing is a type of operation costing which is used to ascertain the cost of a product at each process or stage of manufacture. A process can be referred to as the sub-unit of an organization specifically defined for cost collection purpose.